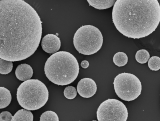

Silica fume

Negotiable Min Order Quantity Unit

- Required Quantity

-

- Place of Origin

- Payment Terms

- Negotiable

- Production method

- Negotiable

- Shipping / Lead Time

- Negotiable / Negotiable

- Keyword

- microsilica, silica fume

- Category

- Silica

Apply a video call to the Supplier

Henan Huaxi Furnace Refractory Co., Ltd

- Country / Year Established

-

China

/

China

/

- Business type

- Others

- Verified Certificate

-

13

| Product name | Silica fume | Certification | - |

|---|---|---|---|

| Category | Silica | Ingredients | - |

| Keyword | microsilica , silica fume | Unit Size | - |

| Brand name | - | Unit Weigh | - |

| origin | Stock | - | |

| Supply type | - | HS code | - |

Product Information

B2B Trade

| Price (FOB) | Negotiable | transportation | - |

|---|---|---|---|

| MOQ | Negotiable | Leadtime | Negotiable |

| Payment Options | Negotiable | Shipping time | Negotiable |

Henan Huaxi Furnace Refractory Co., Ltd

- Country / Year Established

-

China

/

China

/

- Business type

- Others

-

13

- President

- Mr Jiang

- Address

- Huaxi Industrial Area, Beishankou Town, Gongyi, Henan, P.R.China

- Product Category

- Industrial Supplies

- No. of Total Employees

- 101-500

- Company introduction

-

Gongyi City, central China's Henan province. Our factory was established in 1983. After 20 years of hardwork, we have gradually become one professional refractories group company, integrating mining,raw material calcination, refractories manufacture, engineering contracting and research&development of high-tech refractories.

We have mine that has an anual output of 200,000 tons alumina, one factory that manufactures 50,000 tons refractory balls every year, one factory that manufactures 50,000 unshaped refractories every year,one high-tech refractories factory, one research&development department with advanced test equipments, one furnace engineering company with advanced technology, excellent equipments and best services, one service team with experts' comprehensive guidance. We especially focus on the research and development of refractory materials. In 1998 wassed the ISO9001 quality system certification.

We have many patented and core technology products, such as:High strength&heat-insulating fibre gun mixes,erosion resistant spraying coatings,castables for wind tube,non-aqueous compound pressing in mortar and sealed mass, high performance refractories for tap hole runner, environment-friendly waterless tap hole clay, ceramic regenerator,Kalugin ceramic burner,refractory ball made from micro powder and three high, refractory ball made from micro

powder,corundum and mullite. They have already got both home and abroad customers'good reputation because of the high performance.

Our aim: quality first,honesty fundamentality, customers supreme, first class service.

No stablity without domestic market,no strength without overseas market. Now in domestic market, we establish a long-term and strong cooperation relationship with many large iron and steel works because of our excellent quality products,competitive prices and best services. For overseas market, we also establish a well relationship with iron&steel works of Turkey, Russia,

India,etc.At the same time, we work with some refractory factories of Europe, USA, Canada. We learn the leading refractory technology to improve ourselves from time to time. Now we are looking forward to work with more and more iron&steel works from all the countries. If you are intersted in it, please do not hestinate to call us or email us any time! We will do our best to provide the best refractory solutions to you!

- Factory Information

-

Henan Huaxi Furnace Refractory Co., Ltd

- Main Product